- What we do

-

-

Routes of delivery

- Oral

- Nasal

- Nose to Brain

- Pulmonary

- Parenteral

-

Development stage

- Pre-clinical

- Phase I to Phase II

- Phase III - Commercial

Our Approach

- Choosing Your CDMO Partner

- Project Management

-

- About us

-

-

A CDMO like no other

- About Us

- Our Facilities

- Our History

- Awards and Achievements

-

Leadership Expertise

- Executive Leadership Team

- Board of Directors

- Careers

-

-

- Resources

- Events

- Contact

Pharmaceutical

Spray Drying.

A guide to the most versatile

formulation technology in the pharmaceutical industry

What is Pharmaceutical Spray Drying?

Pharmaceutical Spray drying is a simple yet incredibly flexible technology that can transform liquids into powders in seconds.

Manipulation of either the feed solution composition and/or the spray drying process parameters allows the creation of spray-dried powders with a range of both physical and aerodynamic properties.

Whilst formulation and process development for pharmaceutical spray drying can be readily undertaken at a small, even milligram scale if the drug is in short supply, the process is highly reproducible and scalable, with established models allowing straightforward scale up to produce kilograms of material for toxicology and clinical studies.

There are several key features of the spray drying process that can be manipulated to enhance the formulation and delivery of small molecules and biologics. In many cases, several of these features can be combined and as a result the target product performance profile can subsequently be achieved.

Benefits of Spray Drying

Enhanced bioavailability of poorly soluble compounds

Consistent particle size distribution

Alternative to freeze drying to stabilise biologics

Enables modified release dosage forms

Applications of Pharmaceutical Spray Drying.

Pharmaceutical spray drying offers versatile applications in various drug delivery methods.

It excels in particle engineering, making it ideal for pulmonary and nasal delivery systems, where precise particle size and distribution are crucial for effective drug deposition.

Additionally, spray drying facilitates the production of solid dosage forms like capsules and tablets, ensuring uniform drug delivery and dosage accuracy. Furthermore, it enables the creation of solid dispersion systems (SDDs), enhancing bioavailability by improving drug solubility and dissolution rates, thus optimizing therapeutic outcomes.

- Particle engineering – ideal for pulmonary and nasal delivery

- Improved bioavailability by producing SDDs

- Production of solid dosage forms – capsules and tablets

- Modified release – modify PK/sustained release

- Stabilisation of biologicals – a viable, more cost-effective alternative to freeze-drying

Particle engineering

ideal for pulmonary and nasal delivery

Improved Bioavailibility

by producing SDDs

Production of solid dosage forms

capsules and tablets

Modified release

modify PK/sustained release

Spray Dried Particles

API in aqueous solvent +/- excipients as required

Stabilisation of biologicals

a viable, more cost-effective alternative to freeze drying

Spray Drying Process

Pharmaceutical Application

Spray drying a solution of API and excipients to create a dry powder

- Producing dry powders for capsules/tablets

- Stabilisation of biologics (alternative to

freeze drying) - Enhanced solubility/bioavailability of poorly soluble APIs

Spray drying to create particles with defined size/aerodynamic properties

- Engineering powders for nasal delivery

- Engineering powders for pulmonary

delivery

Modified solubility/release by co-spray drying with enteric polymers

- Targeted release of API in the GI tract

- Localised/delayed release profile

Spray Drying Expertise

Upperton is world-renowned for its’ spray drying expertise. We have a range of spray dryers available, from development dryers that can work with the smallest quantities (milligrams) of drug, to pilot-scale dryers that can produce kilogram quantities of powder in a single day of operation. These are available in our research and development facility, and in our GMP facility, meaning that processes can be easily and seamlessly developed, scaled up and then transferred for clinical manufacture.

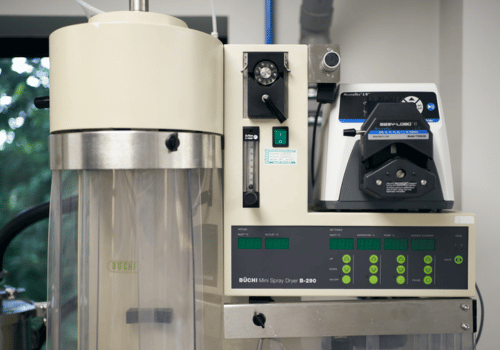

BUCHI Mini Spray Dryer B-290

8 UNITS AVAILABLE

Typical Batch Scale

100mg – 100g

Specialist Capabilities

Air/inert (N2) drying gas

Applications

Early formulation screening and development

ProCepT 4M8-TriX Spray Dryer

3 UNITS AVAILABLE

Typical Batch Scale

100mg – 400g

Specialist Capabilities

2-fluid and ultrasonic atomisation

Applications

Smaller scale GMP processes. Particle engineering for nasal and pulmonary delivery

GEA Niro SD Micro Spray Dryer

1 UNIT AVAILABLE

Typical Batch Scale

5g – 3kg

Specialist Capabilities

Air/inert (N2) drying gas

Applications

GMP manufacturing under nitrogen

GEA Niro MobileMinor Spray Dryer

2 UNITS AVAILABLE

Typical Batch Scale

25g – 5kg

Specialist Capabilities

2-fluid and pressure nozzles

Applications

Larger scale aqueous spray drying

Choosing a CDMO partner

When it comes to choosing a Contract Development and Manufacturing Organisation (CDMO) partner for your pharmaceutical product development, there are several factors to consider.

Firstly, you need to ensure that the CDMO has expertise in spray drying technology. As mentioned earlier, spray drying is a crucial process in formulating poorly soluble drugs and producing various dosage forms. Therefore, the CDMO you choose must have advanced equipment, such as the ProCepT 4M8-TriX Spray Dryer or the GEA Niro SD Micro Spray Dryer, to handle these complex formulation challenges.

Another important factor to consider is the scale-up capabilities of the CDMO. Depending on your project requirements, you may need a CDMO that can handle small-scale development batches, or larger-scale production batches. Having access to a range of spray dryers allows for flexibility in process optimization and ensures that the CDMO can meet your specific needs.

Read more about the factors to consider when choosing a CDMO partner.

Enhance the Solubility and Bioavailability of Poorly Soluble APIs

Manipulation of either the feed solution composition and/or the spray drying process parameters allows the creation of spray-dried powders with a range of both physical and aerodynamic properties.

Whilst formulation and process development for pharmaceutical spray drying can be readily undertaken at a small, even milligram scale if the drug is in short supply, the process is highly reproducible and scalable, with established models allowing straightforward scale up to produce kilograms of material for toxicology and clinical studies.

There are several key features of the spray drying process that can be manipulated to enhance the formulation and delivery of small molecules and biologics. In many cases, several of these features can be combined and as a result the target product performance profile can subsequently be achieved.

Future applications of spray drying in pharmaceuticals

Spray drying as an enabling technology for poorly soluble oral drugs is likely to continue to grow as amorphous materials become more established and widely accepted by the industry. However, future and sizable growth is likely to come from its application in biopharmaceuticals such as in the isolation and preparation of peptides, proteins, and monoclonal antibodies.

The cost and throughput advantage over traditional lyophilization and the ability to deal with far more complex formulations and solvent systems is likely to drive its gradual introduction in these fields.

Aseptic spray drying is still in the early stage of implementation but robust steps have recently been undertaken in the design of these units as well as in aseptic powder filling, a complementing unit operation. Another area of potential growth is the use of spray drying to produce inhalable drugs; one of the major drawbacks associated with conventional lactose blends is the need to balance adhesive-cohesive forces between the drug substance and the carrier, with a significant amount of drug not detaching from the lactose and being inevitably deposited in the mouth/throat; spray drying, as a continuous process, can be used to overcome this challenge by enabling the preparation of composite particles where, via a precise fine-tuning of particle size distribution during development (and tight control during manufacturing), very high and reproducible respirale fractions can be obtained.

Furthermore, spray drying has shown promising results in improving drug bioavailability for poorly water-soluble drugs, making it a valuable technique for future pharmaceutical applications, particularly in addressing the issue of poor bioavailability.

Frequently Asked Questions

What is pharmaceutical spray drying, and how does it work?

Pharmaceutical spray drying is a process that converts a liquid solution or suspension into a dry powder form. It involves atomizing the liquid into fine droplets and then rapidly drying these droplets by exposing them to a stream of hot air or gas, causing the solvent to evaporate and leaving behind solid particles.

What are the advantages of using spray drying in pharmaceutical formulations?

Spray drying offers several advantages in pharmaceutical formulations, including precise control over particle size and distribution, improved solubility of poorly soluble drugs, enhanced bioavailability, ease of scale-up, and versatility in producing various dosage forms such as powders, granules, and microspheres.

What types of pharmaceutical products can be produced using spray drying?

Pharmaceutical spray drying can be used to produce a wide range of products, including inhalable powders for pulmonary and nasal delivery, solid dispersion systems (SDDs) to improve drug solubility, modified release formulations for controlled drug release, and stable formulations of biologics.

What are some API spray drying process considerations?

API processing considerations include:

- Solubility and bioavailability challenges

- Excipient selection

- Solvent selection and removal

We're here to help

If you’re looking to work with a CDMO with extensive experience in overcoming solubility challenges through spray drying, then we’re here to help.

Speak to our team to discuss your requirements.

How does a spray dryer work?

A spray dryer works by atomizing a liquid feed into small droplets, which are then dried rapidly by hot air. The liquid droplets are introduced into a drying chamber where they come into contact with the hot air, causing the water or solvent to evaporate, leaving behind dry particles.