Pulmonary delivery is showing increased popularity as a viable dosage form for treating local airway diseases and offers additional potential for systemic drug delivery. Within this space there are a number of delivery approaches that can be undertaken. These include dry powder inhaled formulations (DPI) and pressurised metered Dose Inhalers (pMDIs).

Each of these delivery options have benefits and limitations and as a result the applications for both differ. However, if the target patient profile allows for it then companies typically look towards using DPIs for their finished product.

When developing a DPI formulation, particle engineering is a major factor in a successful development programme. Indeed, the aerosolisation of the powder is key to delivery of the therapeutic.

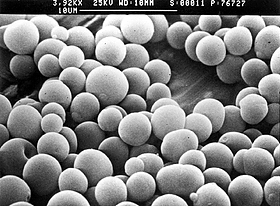

For successful delivery of DPI formulations, the production of small particles with an aerodynamic particle size between 1-5 μm is required to reach the deep lung. There are a number of techniques that can be used to achieve this size range with spray drying being seen as a manufacturing method capable of producing spherical particles with excellent control of size, morphology and aerosolisation behaviour.

Creating particles for optimum delivery can be achieved by careful selection of both the formulation, solution and spray drying parameters. For example, criteria such as feedstock concentration, atomisation pressure and drying temperature all impact on particle morphology and ultimately aerodynamic properties.

One major challenge that occurs during this development phase is one of collection and subsequently process yield. In short, small particles can be produced relatively easily using a standard spray dryer but collection becomes increasingly difficult as the particle size drops below 5 μm. Upperton has devised a two-step manufacturing process called PulmoCraft™ to overcome the scale-up issues associated with producing and collecting small particles for inhaled formulations.

Development of Inhaled Formulations

Spray dried powders tailored for use in inhaled formulations typically consist of a carrier matrix and the API to be delivered. Indeed, the API could be a small molecule or a larger biologic. The PulmoCraft™ process consists of the following steps:

- Initial solubility screening to define an appropriate solvent system for the API and the carrier matrix.

- Once a defined solvent system has been determined, initial spray drying tests are performed to assess the physical properties of the spray dried powders produced.

Tests might include:

- Dynamic Stability Control (DSC)

- Dynamic Vapour Sorption (DVS)

- Particle size

- Particle morphology (SEM)

- Device testing (cascade impactor, emitted dose etc.)

Stability testing of the spray dried powder, both as a bulk powder and filled into a device/capsule is then undertaken on lead formulations.

Scale-up. Increasing batch size for toxicology testing can be a challenge in terms of process yield and through-put. These challenges can be overcome by using dry powder milling to tailor particle size into the desired range.

PulmoCraft™: Process Development and Scale-up of Inhaled Dosage Forms

Developing dry powder dosage forms

Choice of materials:

A major challenge associated with spray dried DPI formulations is identifying a suitable matrix to encompass the API from the limited range of excipients that are seen as suitable for pulmonary delivery from a regulatory perspective. Not only is the choice limited but care needs to be taken that the excipients chosen have good compatibility with the API as well as the ability to form stable and aerodynamically suitable particles.

Optimising Aerodynamic Properties:

A key characteristic which affects the aerodynamic properties are weight / density of a particle. If a particle is heavy it may not travel efficiently leading to an insufficient amount reaching the deep lung. The process of spray drying is known to create particles which have lower density compared to other techniques such as milling.

Optimising Particle Size:

Making and collecting small particles poses a challenge. Spray drying is ideal for particle engineering, the process of creating particles of the desired size, by controlling the processing parameters that form the particles themselves. Typical process parameters that need to be optimised include:

- Increasing the air pressure during the atomisation step and / or reducing the rate in which feed solution is sprayed into the drying chamber to reduce droplet size

- Reducing the concentration of excipients / API within the feed solution (reducing dry powder size)

- Adding water miscible solvents (such as ethanol) to reduce viscosity resulting in reduced droplet size

Scale-up of manufacturing processes

Producing small quantities of spray dried powder for feasibility testing is relatively straight forward. However, increasing batch size is necessary to produce sufficient quantities of powder required for development studies and toxicology testing. This can lead to considerable challenges.

The central challenges on scale-up centre around the need for longer processing times and reduced product yield associated with making and collecting these fine particles; problems that are exacerbated with the switch to larger process spray dryers.

To overcome these scale-up challenges Upperton has developed a two-step solution to this problem; a combination of spray drying and dry powder milling that can be used to increase throughput and yield without deleteriously affecting product yield.

In the first step, larger spray dried particles are first produced on the spray drier with mean particle sizes above 5 µm (which are within the range required for efficient cyclone collection on these machines). These particles can then be reduced to the required size range using dry powder milling, generating particles in the desired 1-5 µm size range whilst maintaining good yields and processing rates.

Using this approach, feed concentration and processing rate can both be increased; significantly reducing both manufacturing time and cost. The spray dried particles are then reduced to the target particle size distribution, using a carefully controlled dry powder milling process. The result is a much faster, more efficient process producing large quantities of powders with excellent aerodynamic properties.

Cascade Impactor testing of our powders produced in this way confirms that it is possible to reproducibly generate dry powders with an aerodynamic particle size distribution of 1-5 µm, with fine particle fraction in excess of 70% when formulated powders are delivered from commercially available DPIs.

To Conclude

Spray drying is an excellent process for producing particles with the right aerodynamic properties needed for deep lung delivery. However, it is important to bear in mind future scale up challenges that will become apparent when processes move from the research / feasibility scale into full development. Increasing the scale of manufacture usually requires the move to larger scale spray dryers with reduced efficiency of collection for small particles.

Upperton’s PulmoCraft™ technology has been developed to overcome these scale-up problems. This is achieved by harnessing the ability of spray drying to produce large quantities of dry powder formulation with the use of dry powder milling to reduce particle size into the correct range needed for successful deep lung delivery. The result is a process that is capable of producing a suitable DPI formulation using a manufacturing process with improved yields and increased processing throughputs.