- What we do

-

-

Routes of delivery

- Oral

- Nasal

- Nose to Brain

- Pulmonary

- Parenteral

-

Development stage

- Pre-clinical

- Phase I to Phase II

- Phase III - Commercial

Our Approach

- Selecting Your CDMO Partner

- Project Management

-

- About us

-

-

A CDMO like no other

- About Us

- Our Facilities

- Our History

- Awards and Achievements

-

Leadership Expertise

- Executive Leadership Team

- Board of Directors

- Careers

-

-

- Resources

- Events

- Contact

Oral Solid

Dosage Forms.

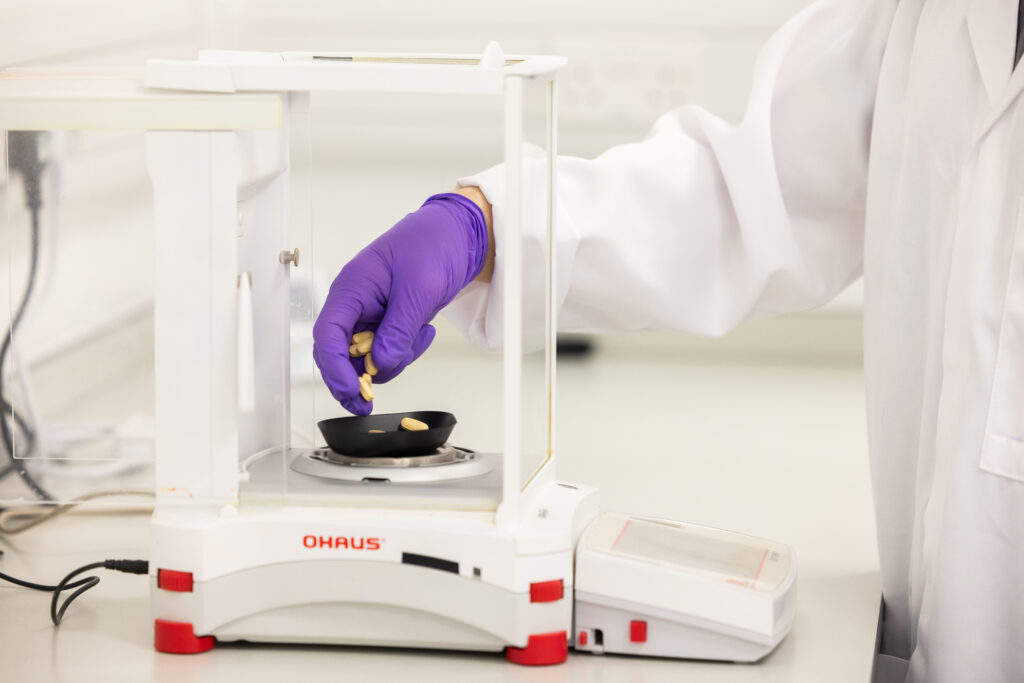

Tablets, powders, capsules and granulation.

Expertise in oral solid dosage forms.

Our approach.

Oral administration remains the most widely used route for the successful delivery of active pharmaceuticals to patients. Upperton is your trusted partner for oral solid dose (OSD) products.

With capabilities covering tablets, powders in bottle/sachet, dry granulation, coated and uncoated tablets and capsules, you can be confident in our expertise in the development and manufacture of oral solid dosage forms.

Guided by a team of experts

Typical OSD development pathway.

Our team offers expert preclinical and clinical formulation development of oral solid dosage (OSD) forms, guiding clients from early feasibility to clinical manufacture. Dosage form design is tailored to factors such as development speed, anticipated dose, excipients to enhance API stability or bioavailability, and targeted or modified release profile requirements.

Preclinical Development

Small scale blends/batches

Clinical Formulation Development

Selection of lead/backup formulations

Scale-up and pilot manufacture to support regulatory submissions

Clinical Manufacture Phase 1-3

Registration/

validation and commercial manufacture

Conventional and SDDs

Tablet formulations.

Whilst capsule delivery represents the faster route into the clinic, tablet formulations give more flexibility in the formulation and offer a more cost-effective solution for products entering later stages of development or commercial manufacture, as well as being a more established approach for targeted delivery.

Conventional

- Particle size/soluble molecules

- Direct blending/dry granulation

- Coating (cosmetic or functional

SDD (Spray Dried Dispersions)

- Poorly soluble molecules

- Dose/API loading

- Disintegration, drug release profile

API, Blend and SDDs

Capsule formulations.

Capsule formulations are often the favoured dosage form for initial clinical studies as they offer a fast, convenient way to deliver the API to the pharmacy.

Capsules may contain simple unformulated API or more advanced formulations, such as amorphous spray-dried dispersions designed to enhance bioavailability.

API

- Dependent on API solubility/BCS class

- Chemical stability required

- API ‘gelling’

Blend

- Common blend or range of blend strengths

- Determine excipient compatibility

SDD (Spray Dried Dispersions)

- Poorly soluble molecules BCS II/IV

- Powder flow/need for compression

- Dispersion/drug release profile

Analytical testing

Phase-appropriate methods are developed for analysis of OSDs from early-stage development, through to GMP manufacture.

- Appearance – visual and microscopic

- Material identification (FTIR)

- Assay and related substances (HPLC, UV, GC)

- Water content (Karl Fischer)

- Residual solvents (GC)

- Blend homogeneity

- Blend density/compressibility

- Content uniformity/weight uniformity

- Tablet hardness/friability

Stability testing

During the preclinical stage, accelerated stability studies focus on excipient compatibility, where API and excipients are blended together and stability assessed with ASAPprime®.

More formal ICH stability studies are used during development to determine product stability/shelf life on technical and clinical batches manufactured under GMP conditions.

Frequently Asked Questions

What are oral solid dosage forms, and why are they commonly used?

OSDs include tablets, capsules, powders, and granules. They are the most common drug delivery method due to their convenience, stability, precise dosing, and ability to protect the active pharmaceutical ingredient (API) during storage and transport.

What are the key manufacturing processes for OSDs?

- Granulation: Wet or dry methods are used to improve powder flow and compressibility.

- Compression and Encapsulation: Converts powders or granules into tablets or capsules, respectively.

- Coating: Enhances stability, controls release profiles, or masks taste.

These processes must meet stringent quality and safety standards

How do controlled-release OSDs work?

Controlled-release formulations deliver APIs over a set period to improve efficacy and patient compliance. Techniques like coating granules or layering APIs in capsules allow for immediate, sustained, or delayed release, tailored to therapeutic needs