Outlining the Trends and Challenges in the Inhaled Drug Delivery Market

The increase in respiratory diseases worldwide, coupled with the potential for systematic drug delivery, has led to a shifting landscape within inhaled drug delivery. As an alternative to pressurised metered dose inhalers (pMDIs), dry powder inhaler (DPI) formulations have the potential to meet the evolving market trends and deliver the next generation of inhaled therapeutics.

In this article, Richard Johnson, Founder of Upperton Pharma Solutions, will outline the trends and challenges within the inhaled drug delivery market, with a special focus on DPI delivery and how challenges with dry powder formulation can be overcome.

Trends Paving the Way for the Evolution of the Inhaled Drug Delivery Market.

Chronic respiratory disorders, including asthma, lung cancer and chronic obstructive pulmonary diseases (COPDs), have been categorised as a leading cause of global mortality and morbidity by the World Health Organisation (WHO)1. WHO estimates that approximately 235 million people worldwide suffer from asthma, and more than 3 million people die every year from COPDs1.

Due to the rapid and targeted delivery of drugs to the airways and lungs, inhalation remains the most common approach to the prevention and treatment of chronic respiratory disorders1. Although pMDIs have traditionally been the inhaled delivery method of choice, a shifting market landscape opens opportunities for alternative methods, such as DPIs.

Dry powder formulations have the potential to deliver the next generation of inhaled therapeutics due to their distinct set of advantages. These include:

Sustainable Inhaled Drug Delivery

Propellants used within pMDIs are usually hydrofluorocarbons (HFCs), which have a high global warming potential (GWP). The high-GWP properties in currently used pMDI propellants mean that they have become a target for increased sustainability within the pharmaceutical industry, with legislation aiming to reduce the use of HFCs in key pMDI markets.

Despite progress in low-GWP propellants, ongoing regulatory changes create uncertainty about the sustainability of propellants, making it unclear where to direct investment. The uncertainty in the propellant market has led to an increased interest in DPIs, which do not use propellants and offer a sustainable inhalation solution.

Stable Biologics Delivery

The development of new treatments based on complex and larger biologics has increased interest in DPIs. Challenges related to the retention of tertiary structure and the need for stability draw attention to DPI’s, which are more suited to the delivery of biologics than pMDI’s.

Whilst aqueous biologics formulations can show increased sensitivity to degradation and loss of efficacy, dry powder formulations of biologics are inherently more stable, providing an innovative solution for product formulation. Adopting dry powder formulations for biologics therefore increases shelf life and maintains the efficacy of the product.

Deep Lung and Systemic Delivery

Another important property of dry powder formulations is the area of the lungs to which they deliver the drug. Biologics, and in particular vaccines, need to be delivered into the deep regions of the lung, which DPIs can achieve far more effectively than most pMDI’s. The ability to deliver drugs deeper into the lungs paves the way for systemic delivery.

Overcoming the challenge of introducing drugs into the bloodstream through the lungs is a substantial task, but entirely possible. Systemic delivery via inhalation could then lead to self-administered pulmonary products, replacing therapies that would traditionally be administered via injection.

Meeting the Growing Demand for Dry Powder Inhaler Delivery.

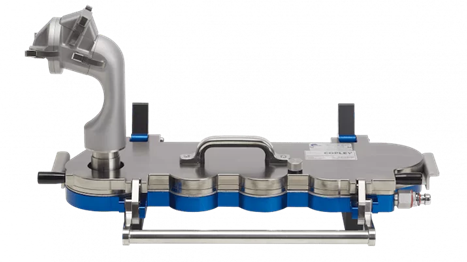

To successfully bring DPIs to market, key milestones must be achieved. The quickest way to meet these demands is to start with the simplest drug formulation possible (small molecule or biologic) and focus on commercially available DPI devices. Capsule-based delivery devices show potential for fulfilling the growing demand.

Dry powder formulations can be packaged into a capsule and then loaded into a commercially available delivery device. Using standard capsules and commercial devices mean that the pathway to the clinic is quicker and more cost-effective than developing proprietary devices.

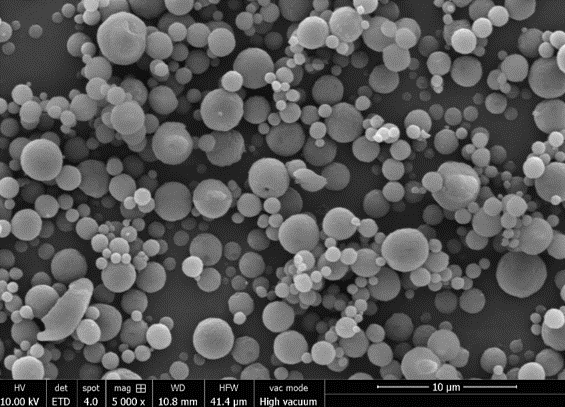

Well-established techniques for DPI formulation, such as spray drying, also ensure that drug particles are the correct size for delivery, simplifying another development step.

Navigating the Hurdles Facing Dry Powder Formulation.

(i) Choice of Excipients

The selection of excipients is one of the main challenges in the delivery of next-generation inhaled therapeutics. Excipients improve aerodynamic properties and the stability of the product and are therefore essential when working with unstable biologics. However, there are very few excipients that are approved for pulmonary use, and many commonly used excipients show incompatibility issues with biologics.

In other dosage forms, such as oral or nasal delivery, biologics have been successfully formulated and stabilised with a range of excipients including monosaccharides, oligosaccharides, amino acids and surfactants, which further highlights the need for the emergence of novel excipients in DPI delivery.

Precedent excipients can help to overcome challenges with pulmonary excipients. Even if they have not been specifically approved by the FDA, precedent excipients will have been used before and during clinical development, which can help ease the pathway to regulatory approval.

Delivering the correct dose of the drug product is another challenge with DPIs. Dose issues centre around the capacity of DPI capsules, which is typically 20-30 mg of powder. The capacity of DPI capsules therefore dictates the formulation of drugs into dry powders, as there is a finite range of how much drug can be delivered. A limited capacity affects some therapeutics more than others, but altering spray drying conditions and drug to excipient ratios helps to optimise formulations and particle sizes.

(ii) Analytical Testing

Regulatory compliance must also be considered to provide a safe and efficacious therapy to patients. It is critical to demonstrate the stability of the active ingredient through the packaging and delivery process. Reproducibility must be tightly controlled when filling capsules and when the drug is delivered from the DPI device. It must also be demonstrated that the active ingredient is reaching the target site within the lungs.

Using a number of analytical techniques to generate efficacy and safety data at an early stage is a key approach to demonstrating regulatory compliance. Light scattering and laser-based approaches can provide information regarding the geometric size of particles. Geometric particle size is an indicator of the aerodynamic properties of DPIs and how the product deposits during inhalation.

The aerodynamic properties of the formulated drug needs to be assessed when filled and subsequently delivered from the device to determine the properties of the product in real-life situations. Analysis with a next-generation impactor is an advanced methodology that can predict how the powder will be delivered and which areas of the lung the product will reach.

The chemical properties of the product are equally as important as the physical properties when determining efficacy and safety. Analytical techniques such as HPLC are used to determine whether the drug has been damaged during spray drying or formulation as well as storage. Dry powder formulations can absorb moisture readily, making thermographic analysis essential to determine moisture content. Microbial testing is also critical to avoid product contamination.

Looking to the Future of Dry Powder Inhalers.

Inhaled therapeutics is an area of the pharmaceutical industry that is in high demand and is set for continued growth in the future. The global increase in respiratory diseases and uncertainty surrounding pMDIs has heightened interest in DPI devices. The compatibility with biologics and the ability to deliver drugs deeper into the lung (which also unlocks the potential for systemic delivery), means that DPI devices have great potential within the growing inhaled therapeutics market.

As the landscape evolves and challenges are addressed, unlocking the potential of DPIs remains crucial for advancing the next generation of inhaled therapeutics. The selection of excipients, dose and formulation of dry powders, and physical and chemical properties must all be considered in the development of new DPI therapeutics. Partnering with specialists in DPI devices and dry powder formulations can bring the knowledge, expertise and technologies required to turn the DPI potential into reality.

Reference

1. Visit: ncbi.nlm.nih.gov/pmc/articles/PMC7499344/

Get in touch.

If you’re looking to work with a CDMO that can support your product from preclinical development to market and beyond, then we’re here to help.