An Introduction to Capsule Formulation Development

Capsule formulation development is critical in the pharmaceutical industry. Capsules offer advantages like ease of swallowing, taste masking, and customisable release profiles. These benefits make capsules a preferred choice for drug delivery systems. Pharmaceutical companies often favour capsules for their streamlined development timelines and simple manufacturing processes.

The encapsulation process involves filling active pharmaceutical ingredients (API) into either hard gelatin or soft gelatin capsules. Each type has distinct properties and applications in drug therapy. Pre-formulation studies and excipient selection are essential to ensure product stability and effectiveness.

Discover Upperton's Oral Dosage Form Capabilities

Oral administration remains the most widely used route for the successful delivery of active pharmaceuticals to patients. Discover how a CDMO partnership can streamline your drug development journey.

Understanding Capsule Formulation Development

Capsule formulation development focuses on creating effective dosage forms for oral drug delivery. This involves selecting excipients, encapsulating APIs, and ensuring product stability.

Capsules are versatile and support various release profiles for different drugs. Pre-formulation studies help determine API-excipient compatibility and the desired release characteristics. Capsule-filling technologies have advanced, offering streamlined development timelines and cost-effective manufacturing. Understanding capsule formulation helps overcome challenges like excipient incompatibility or poor drug release profiles.

The Importance of Capsule Formulation

Effective capsule formulation is vital for multiple reasons. Capsules are versatile in delivering solid and liquid medication. Encapsulating APIs into capsules provides a convenient, single-dose delivery system.

Capsule formulation also offers customizable release profiles, which can enhance treatment outcomes and patient compliance. Timed or sustained-release capsules address different therapeutic needs. The simplicity of capsule-filling technology contributes to faster development and cost efficiency.

The growing use of capsules highlights their importance in pharmaceuticals. Capsules ensure product stability and offer a user-friendly oral form appreciated by both healthcare providers and patients. Their continued effectiveness underscores their role in drug delivery and patient care.

Key Components of Capsule Formulation

The API is the main ingredient responsible for therapeutic effects. Excipients are inert substances that aid in manufacturing, stability, and drug release. Selecting the right excipients ensures product safety and effectiveness. The capsule shell material affects the physical and chemical properties of the capsule, influencing drug release and stability.

Common shell materials include gelatin and hydroxypropyl methylcellulose (HPMC). Gelatin capsules are derived from natural sources and offer biocompatibility. HPMC capsules, on the other hand, are vegetarian-friendly with superior moisture barrier properties. Choosing these components wisely is fundamental to successful capsule formulation.

Oral Solid Dosage Forms: Choices for FIH Studies

Types of Capsules and Their Applications

Hard gelatin capsules are a popular choice in pharmaceuticals. They are made of two parts: a body and a cap, typically composed of gelatin and water. These capsules offer ease of swallowing, making them suitable for both children and adults. Hard gelatin capsules can encapsulate both liquid and dry formulations. They protect APIs from environmental factors and maintain product integrity. They are also available in various sizes and colors, ensuring easy identification and branding. The combination of functionality and simplicity makes them a reliable choice in drug delivery.

Soft gelatin capsules provide a convenient form for encapsulating liquids and semi-solids. The encapsulation process involves filling the shell with a liquid or gel-like formulation, offering versatility in drug delivery.

Soft gelatin capsules offer improved stability and shelf life due to their hermetically sealed design. The encapsulation process includes formulation preparation, shell formation, drying, and inspection. These capsules combine ease of manufacturing with superior drug delivery capabilities.

Capsules are a popular dosage form due to their versatility in delivering both solid and liquid medication. The development process often involves the encapsulation of active pharmaceutical ingredients into capsules, providing a convenient and precise single-dose delivery system.

Pre-Formulation Studies for Capsule Development

Pre-formulation studies are essential in capsule development. These studies focus on understanding the API’s physical and chemical properties and selecting compatible excipients.

Excipient Compatibility Studies ensure the final formulation remains stable and effective throughout its shelf life. Ingredients like HPMC and gelatin require thorough evaluation during pre-formulation.

Analytical Methods in Pre-Formulation

Analytical methods are critical in pre-formulation studies. They determine the physical and chemical properties of APIs and their interactions with excipients. Common methods include:

- Spectroscopy: Used to analyze API composition and purity.

- Chromatography: Helps in assessing drug stability and concentration.

- Microscopy: Provides insights into particle size and morphology.

Excipient Compatibility and Selection

Excipients play a crucial role in capsule formulation by enhancing stability, bioavailability, and therapeutic performance. Compatibility studies are conducted to assess interactions between APIs and excipients. Key factors include: solubility, chemical reactivity, physical compatibility.

Choosing compatible excipients ensures that the capsule formulation maintains API stability and therapeutic effectiveness. Excipients must also meet manufacturing requirements, regulatory guidelines, and patient acceptability criteria. Proper excipient selection is vital for developing safe and effective capsules.

The Formulation Process of Capsules

The capsule formulation process includes pre-formulation studies, excipient selection, and capsule filling. Pre-formulation studies help in understanding API characteristics, while excipient compatibility ensures product stability.

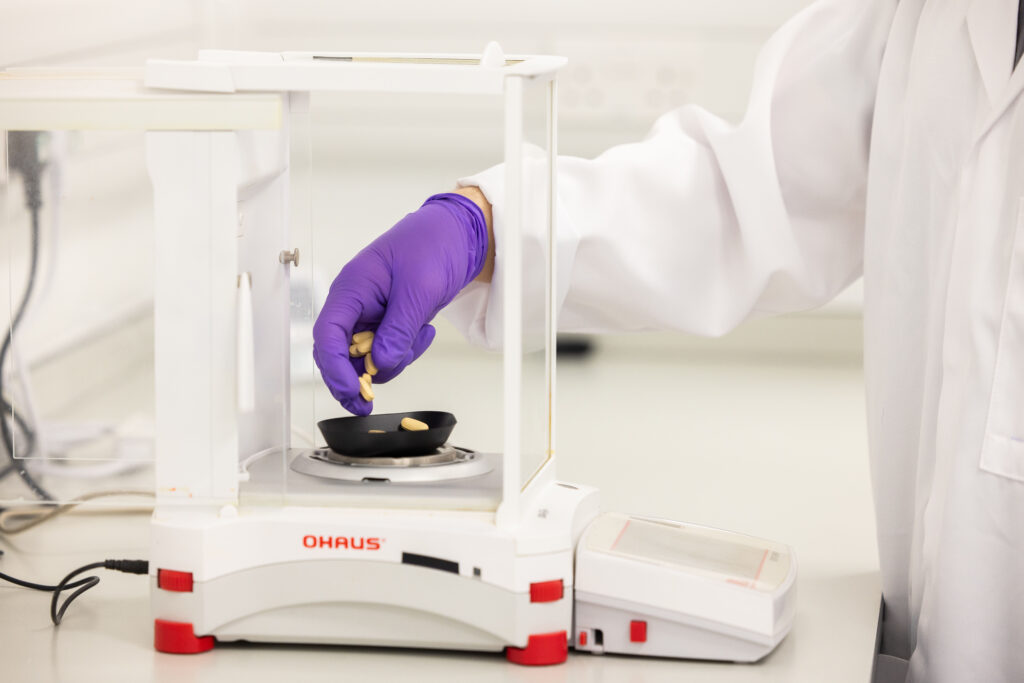

Capsule Filling is the final step. In small-scale operations, capsules can be filled manually. In large-scale production, automated capsule-filling machines are used. This simplicity in capsule filling makes it a preferred choice in pharmaceutical manufacturing.

Discover Upperton's Capabilities

Step-by-Step Guide to Capsule Formulation

- Conduct Pre-Formulation Studies: Analyze API characteristics to understand its properties.

- Select Suitable Excipients: Ensure excipients are compatible with the API.

- Choose Capsule Type: Decide on hard or soft capsules based on the formulation needs.

- Determine Size and Shape: Choose capsule size, shape, and fill weight.

- Use Capsule Filling Technology: Use filling machines to fill capsules with APIs and excipients.

- Apply Granulation Techniques: Use granulation if needed to improve flow and compressibility.

Challenges and Solutions in Capsule Formulation

Formulating capsules presents challenges like achieving consistent drug release profiles, maintaining product stability, and scaling up manufacturing. Common challenges include excipient incompatibility, poor release profiles, and uniform dosage form issues. Solutions include:

- Improving Filling Technology: Advanced machines enhance precision and efficiency.

- Optimizing Excipient Use: Choosing excipients that enhance compatibility and stability.

- Conducting Pre-Formulation Studies: Identifying potential formulation issues early on.

Advancements in sustained-release formulations and innovative filling technologies help overcome these challenges, ensuring capsule effectiveness and stability.

Innovations in Capsule Filling and Sealing

Technological innovations have transformed capsule filling and sealing. Modern machines offer:

- Automatic Capsule Separation

- Weight Control Mechanisms

- Sealing Systems

Digital integration and real-time monitoring enhance quality control during encapsulation. AI-driven algorithms optimize formulations, ensuring the desired release profiles and shelf life. These advancements streamline development timelines and improve capsule reliability and safety.

Quality Control and Stability Testing

Quality control and stability testing are essential to maintain the integrity and performance of capsule formulations. These processes include:

- Parameter Monitoring: Ensuring consistent capsule characteristics throughout production.

- Shelf-Life Testing: Assessing long-term stability under various storage conditions.

Compliance with Good Manufacturing Practices (GMP) and stringent documentation ensures adherence to regulatory requirements, safeguarding patient safety and product efficacy.

Regulatory Considerations in Capsule Manufacturing

Meeting regulatory standards is critical in capsule manufacturing. Authorities like the FDA and EMA oversee the entire manufacturing process, ensuring safety, efficacy, and compliance.

Good Manufacturing Practices (GMP) cover: facility design, equipment calibration, personnel training, production and quality control procedures.

Accurate documentation of raw materials, batch formulations, production steps, and packaging is mandatory. Inadequate documentation can result in regulatory audits, product delays, or compliance issues.

Future Trends in Capsule Development

Future trends include using novel materials for capsule shells, like synthetic polymers and plant-based alternatives, which offer better stability and compatibility.

3D printing enables personalised capsule production, allowing customization in size, shape, and release profiles, catering to specific patient needs. AI optimises formulations by analysing large datasets, predicting API interactions, release profiles, and formulation stability. AI accelerates development timelines, reduces costs, and improves drug quality.

Conclusion

In conclusion, the advancements in capsule formulation development, coupled with the integration of artificial intelligence, are reshaping the landscape of drug delivery and personalised medicine. The focus on customisation and encapsulation techniques like microencapsulation and nanoencapsulation highlight the industry’s commitment to enhancing drug efficacy and patient outcomes.

Let's work together

How can we help you?

Frequently Asked Questions

What are the most common issues in capsule formulation?

Some of the most common issues encountered in capsule formulation include drug stability, compatibility with excipients, and achieving the desired drug release profiles. Other challenges involve selecting the appropriate capsule shell material, such as gelatin or hydroxypropyl methylcellulose (HPMC), and ensuring compatibility with different drug formulations.

How do researchers determine the ideal dosage for a capsule formulation?

Researchers determine the ideal dosage for a capsule formulation through a series of studies involving pharmacokinetics, bioavailability, and clinical trials. Factors such as the drug’s therapeutic range and patient demographics are considered to ensure the effectiveness and safety of the final product.

What are the key factors considered when designing a capsule formulation?

Key factors considered when designing a capsule formulation include the chemical and physical properties of the active ingredient, desired release profile, stability requirements, patient convenience, manufacturability, regulatory compliance, and cost-effectiveness. Additionally, considerations such as compatibility with excipients, bioavailability enhancement strategies, and potential interactions with the encapsulation material play a crucial role in optimizing capsule formulations for efficacy and safety.