When customers initiate discussions with Upperton, one of the first questions we are asked is “which spray dryer(s) do you have and how much material can they produce?”

Whilst these are very pertinent questions, the answer is not a simple one.

Selection of a spray dryer that is appropriate for the project in question needs to take into account a number of key factors. These are varied and may be driven by one or more of the following considerations:

- The quantity of API available for development studies

- The potency and handling characteristics of the API

- The amount of dry powder formulation required (batch size)

- The solids content of the feed solution and the batch size will dictate the volume of liquid to be spray dried per batch – a spray dryer with suitable evaporative capacity will be selected

- The solvent(s) used to make up the feed solution (aqueous, organic or mixed systems) will dictate whether the drying gas will be air or nitrogen

- Atomisation method – spray dryers can use two-fluid, sonicating or pressure spray nozzles.

- Target particle size distribution (particle engineering) – spray dryers use a cyclone collection system; cyclone design will impact on the size range of particles collected

- Stage of development (feasibility studies, formulation/process development or GMP clinical manufacture)

At Upperton, we have a range of pharmaceutical spray drying equipment and selecting which one is appropriate for a particular study will involve consideration of all of the above factors.

Pharmaceutical Spray Drying at Upperton

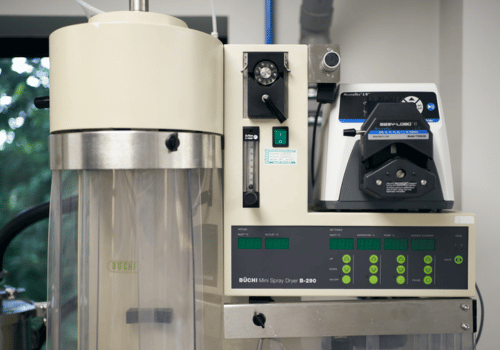

In our R&D labs, we have two types of laboratory-scale development spray dryer: The Buchi B290 and the ProCepT 4M8-TriX. The B290s can be fitted with an inert closed loop system for spray drying flammable solvents or delicate APIs under nitrogen.

Scale up to a GEA Niro Mobile Minor spray dryer is initially performed within our non-GMP pilot plant, where 2-3 kg batches can be produced for toxicology studies or tablet formulation development studies.

Within our GMP manufacturing facility, we have a ProCepT 4M8-TriX spray dryer for small scale clinical material (up to 300 g batch size) and a GEA Niro Mobile Minor for larger scale (up to 3 kg batch size) clinical manufacture from aqueous feed solutions. Clinical manufacturing from solvent-based feed solutions is performed using our GEA Niro SD Micro spray dryer, under nitrogen in an open loop configuration.

BUCHI Mini Spray Dryer B-290

8 UNITS AVAILABLE

Typical Batch Scale

100mg – 100g

Specialist Capabilities

Air/inert (N2) drying gas

Applications

Early formulation screening and development

ProCepT 4M8-TriX Spray Dryer

3 UNITS AVAILABLE

Typical Batch Scale

100mg – 400g

Specialist Capabilities

2-fluid and ultrasonic atomisation

Applications

Smaller scale GMP processes. Particle engineering for nasal and pulmonary delivery

GEA Niro SD Micro Spray Dryer

1 UNIT AVAILABLE

Typical Batch Scale

5g – 3kg

Specialist Capabilities

Air/inert (N2) drying gas

Applications

GMP manufacturing under nitrogen

GEA Niro MobileMinor Spray Dryer

2 UNITS AVAILABLE

Typical Batch Scale

25g – 5kg

Specialist Capabilities

2-fluid and pressure nozzles

Applications

Larger scale aqueous spray drying

Selecting the Appropriate Spray Dryer

The process requirements and selection of appropriate spray dryer are summarised in the table below:

Process Requirement

Spray Dryer of Choice

Rationale

Multiple small batches (early feasibility studies)

Büchi B290

Quick and easy to set up and clean down. Can produce batch sizes of 100 mg to 100 g.

Particle engineering of dry powders for pulmonary or nasal devices

ProCepT 4M8-TriX

Particles of 1-150 µm can be produced. A range of two-fluid nozzle tips (0.15 mm to 1.2 mm) are available to control droplet size and allow fine tuning of the particle size. An ultrasonic nozzle is also available for production of very large particles.

Solvent spray drying (development batches)

Büchi B290

An inert loop is available for spray drying flammable solvents under nitrogen (closed loop).

Solvent spray drying (clinical manufacture)

GEA Niro SD Micro

Flammable solvents are spray dried under nitrogen with an open loop system to avoid cross contamination.

Potent APIs (non-GMP)

Büchi B290

ProCepT 4M8-TriX

The B290 can be sited within a walk-in fume hood and the ProCepT 4M8-TriX can be enclosed within an isolator for more potent APIs.

PC control of process parameters and data

ProCepT 4M8-TriX

Computerised control unit with recording and reporting of critical process data.

Larger scale non-GMP batches (aqueous systems, up to 30 L feed solution)

GEA Niro Mobile Minor

Spray dryer situated in Upperton non-GMP pilot plant. Ideal for producing 2-3 kg material for toxicology / stability studies or dosage form development studies.

Clinical manufacture (aqueous systems, up to 2.5 L feed solution)

ProCepT 4M8-TriX

Spray dryer sited within our GMP manufacturing facility.

Clinical manufacture (aqueous systems, up to 30 L feed solution)

GEA Niro Mobile Minor

Spray dryer situated in Upperton GMP facility. Ideal for producing 2-3 kg batches of clinical material.

Let's work together

How can we help you?

Get in touch.

If you’re looking to work with a CDMO that can support your product from preclinical development to market and beyond, then we’re here to help.