- What we do

-

-

Routes of delivery

- Oral

- Nasal

- Nose to Brain

- Pulmonary

- Parenteral

-

Development stage

- Pre-clinical

- Phase I to Phase II

- Phase III - Commercial

Our Approach

- Selecting Your CDMO Partner

- Project Management

-

- About us

-

-

A CDMO like no other

- About Us

- Our Facilities

- Our History

- Awards and Achievements

-

Leadership Expertise

- Executive Leadership Team

- Board of Directors

- Careers

-

-

- Resources

- Events

- Contact

Successful Scale-Up of a Spray Dried Formulation for Nasal Drug Delivery.

This scientific poster seminar will explore relevant solutions for the successful scale-up of a spray dried formulation for nasal drug delivery.

Poster overview

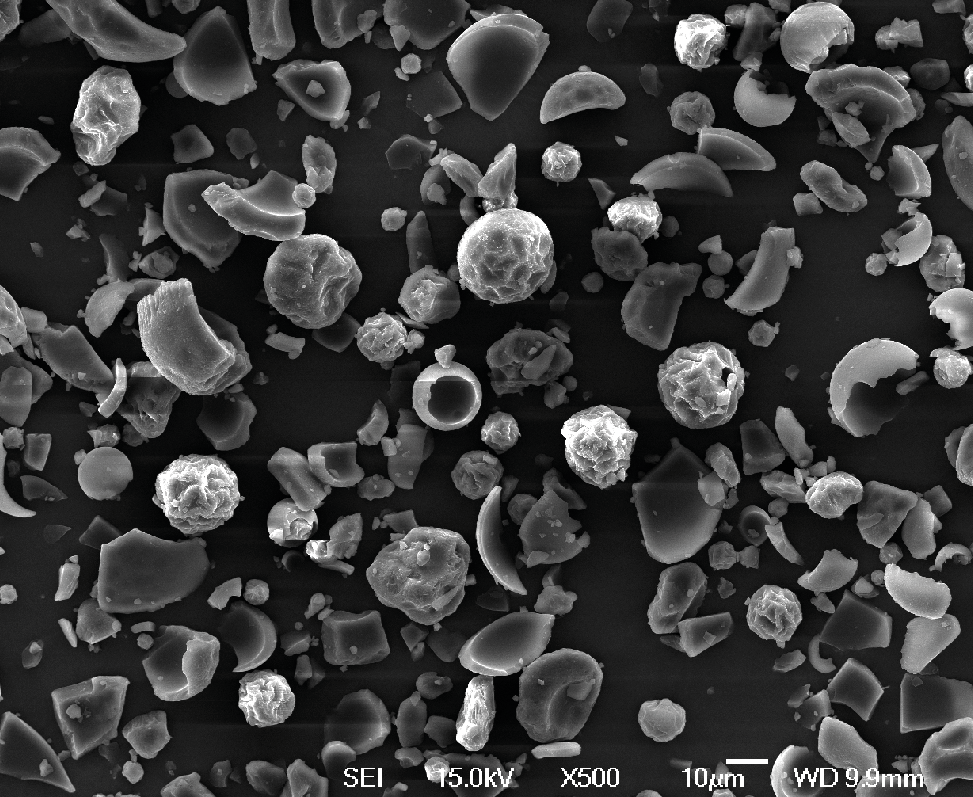

Spray drying is a simple and flexible technology that can transform a liquid feed solution into a powder in seconds. There are multiple key features of the spray drying process which can be manipulated to target a specific product profile; for example, the method of atomising the feed allows for manipulation of the particle size of the resultant dry powder.

The ability to target and maintain a specific particle size is integral for controlling the behaviours of a formulation, such as its flowability, dissolution, and aerodynamic properties. In the case of nasal formulations, the particle size is particularly important for controlling the deposition of powder, and limiting the amount of the formulation which enters the lungs.

Our internal research has explored how the scale up of a spray drying process across a range of spray dryers and nozzles can impact the particle size, morphology, and deposition profiles produced. From this research, we were able to demonstrate:

Successful scale-up: Spray dried formulation transitioned effectively from laboratory to commercial scale spray dryer, utilising a range of nozzle types.

Favourable nasal deposition profiles: Majority powder deposition observed in the nasal region (AINI) with minimal lung deposition (NGI), despite generation of significant sub-10µm particles for some formulations.

Feasibility of multiple scale-up routes: Results indicate potential for various approaches in producing nasal powders, with negligible impact on total AINI deposition, particularly when using active nasal devices.

Further experimentation would be necessary to assess formulation and device type influence on deposition profiles.

Meet our experts

Lara Penn

Senior Development Scientist II, Upperton Pharma Solutions

Dr. Richard Johnson

Chief Scientific Officer & Founder,

Upperton Pharma Solutions

Dr. Ian Lafferty

Chief Technical Officer,

Upperton Pharma Solutions