An Overview of Clinical Trial Manufacturing

Clinical trial manufacturing is a specialised process focused on producing drugs for clinical research. This includes following Current Good Manufacturing Practice (cGMP) guidelines, understanding the differences between clinical and commercial manufacturing, and leveraging the benefits of specialty clinical trial manufacturing services on a smaller scale.

Clinical research is the third stage of drug development. It evaluates a drug’s safety and effectiveness by testing it on human subjects. This step gathers critical data about the drug’s performance and potential side effects. For clinical research, drugs are made specifically for trials rather than commercial sale.

Understanding Clinical Trial Manufacturing

Clinical trial manufacturing, also known as Clinical Trial Material Manufacturing (CTM), requires precision and flexibility. While clinical and commercial manufacturing overlap, clinical manufacturing has unique challenges. This is where contract development and manufacturing organisations (CDMOs) play a key role. CDMOs have the expertise to develop and produce FDA-approved clinical trial materials. They handle formulation development, cGMP guidelines, clinical trial data management, supply chain logistics, packaging, and more. Their support helps you move seamlessly from clinical trials to market readiness.

Before manufacturing clinical trial materials, you should create a detailed plan and timeline. A knowledgeable CDMO can help set realistic timelines for your specific drug development project.

Defining Clinical Trial Manufacturing

Clinical trial manufacturing includes the production of drugs that are in the research phase of clinical studies. This includes Phase I, II, and III clinical trials. You need a detailed plan and timeline before submitting an investigational new drug file or an investigational medicinal product dossier. Clinical trial manufacturing must adhere to strict guidelines and accommodate the unique challenges of clinical research.

By following cGMP guidelines, clinical manufacturing maintains the integrity and consistency of clinical trial materials. This is crucial since formulations and dosages may still change during research. Consistent materials are necessary for accurate data collection.

Clinical research is the third stage of the drug development process and is crucial for evaluating the safety and efficacy of new drugs before they can be approved for commercial use

The Importance of Clinical Trials in Drug Development

Clinical trials are critical for drug development. They come after preclinical research and test a drug on human subjects to assess safety, efficacy, and side effects. During late-stage Phase III studies, large-scale clinical trials gather data to support decisions about drug development and regulatory approval.

The data from clinical trials determines optimal dosage, administration routes, and potential side effects. It also helps developers compare the drug to existing treatments. This ensures that new drugs are safe, effective, and provide real benefits to patients.

Clinical trials also drive medical progress. They offer patients access to new treatments and contribute to therapies that improve future healthcare outcomes.

Essential Guide to Clinical Trial Manufacturing

Key Steps in Clinical Trial Manufacturing

Clinical trial manufacturing involves several steps to ensure high-quality materials. These steps include the design and development phase, selecting materials and suppliers, and adhering to cGMP guidelines.

Design and Development Phase

During the design and development phase, you focus on drug formulation development and creating a plan and timeline for manufacturing.

Formulation development includes selecting the right excipients, determining the best route of administration, and ensuring stability and bioavailability. A well-structured plan and timeline ensure that the drug is available on schedule for clinical trials.

An experienced CDMO can guide you through this phase, ensuring a smooth transition from clinical manufacturing to market readiness.

Selection of Quality Materials and Suppliers

Choosing quality materials and suppliers is critical to maintaining the integrity and consistency of clinical trial materials. Good manufacturing practices and adherence to strict quality standards are essential in this step.

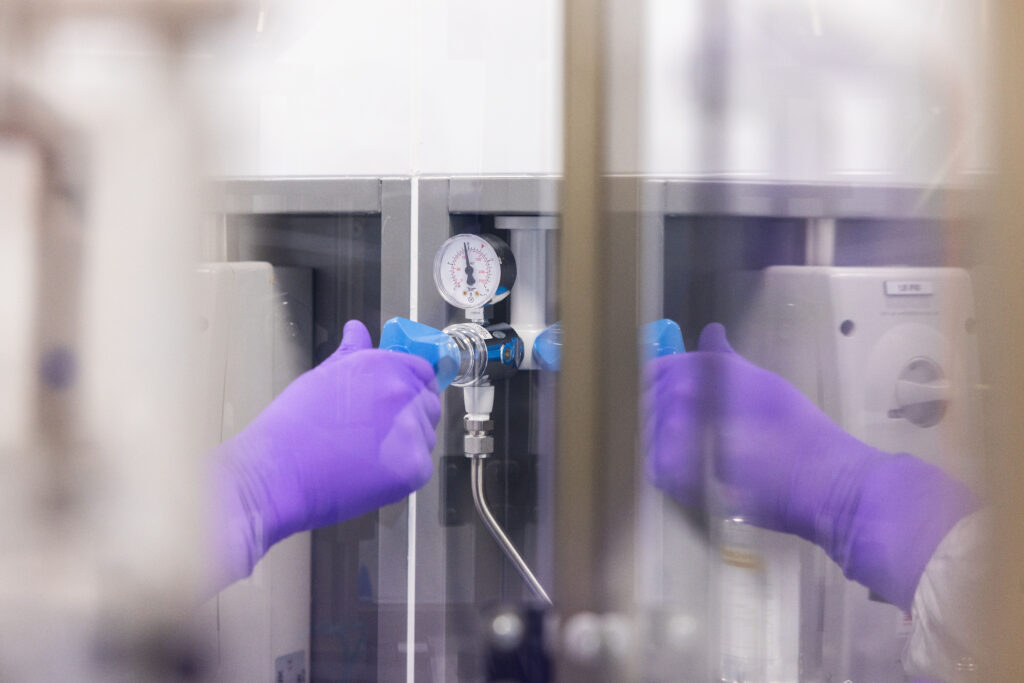

Using disposable equipment, pre-sterilized containers, and closed-process systems helps minimize contamination risks. CDMOs can offer guidance on selecting reliable materials and suppliers while following cGMP guidelines to maintain clinical trial material integrity.

Adhering to cGMP guidelines ensures drug safety and efficacy in Phase I and II development. These guidelines apply to various drug types, including vaccines, gene therapy, and small molecules. Early implementation of cGMP builds a robust quality management system (QMS).

Overview of cGMP Guidelines

cGMP guidelines ensure pharmaceutical drugs are consistently produced and controlled according to established quality standards. Regulatory agencies, like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), set these guidelines. They cover manufacturing, packaging, labeling, and testing processes.

cGMP guidelines include requirements for personnel, facilities, equipment, component control, manufacturing records, lab controls, packaging, and record-keeping. Adhering to these guidelines guarantees the safety and consistency of clinical trial materials while complying with regulatory requirements.

Current Good Manufacturing Practices (cGMP) in Clinical Trials

Clinical trial manufacturing strictly follows cGMP guidelines to maintain quality and compliance. These guidelines outline the production and testing standards for investigational medicinal products. Adhering to cGMP ensures that clinical trial drugs meet human-use quality standards, building trust in the clinical process.

Implementing cGMP involves having a comprehensive written quality control plan. This includes guidelines for personnel, facilities, equipment, components, manufacturing processes, lab controls, packaging, and record-keeping.

A CDMO can help implement cGMP guidelines, ensuring compliance and operational efficiency throughout the clinical manufacturing process.

Navigating Regulatory Requirements

Navigating regulatory requirements is a key part of clinical trial manufacturing. Regulatory agencies like the FDA and EMA establish guidelines to ensure clinical trial material safety, efficacy, and integrity. Compliance involves following Good Manufacturing Practices (GMP), submitting required documentation, and meeting agency guidelines.

CDMO Partnerships for Clinical Trial Supply Success

FDA Regulations for Clinical Trial Manufacturing

FDA regulations are outlined in Title 21 of the U.S. Code of Federal Regulations, specifically Parts 210 and 211. These parts cover manufacturing, packaging, labeling, and testing drugs intended for human use.

For Phase I studies, clinical trial materials are exempt from Parts 210 and 211 requirements. However, compliance with these regulations becomes mandatory in Phase II and Phase III studies. The FDA also provides GMP guidance for investigational drugs in Phase I clinical trials. Adhering to these guidelines ensures the safety and quality of clinical trial materials.

EMA Guidelines and Their Impact

The European Medicines Agency (EMA) sets regulations for manufacturing clinical trial materials. EMA guidelines cover manufacturing processes, quality control, record-keeping, and labeling. Compliance with these guidelines is critical for regulatory approval.

The EMA conducts inspections to verify compliance and harmonizes GMP activities across the European Union (EU). Manufacturers aiming to distribute products in the EU must meet GMP requirements, regardless of their location. Failure to comply can result in delays and hinder clinical trial progress.

Advances in Technology and Their Role

Technological progress enables targeted therapies and personalized medicine. Innovations like nanoparticles and microencapsulation improve drug stability and bioavailability.

Gene therapy also benefits from advanced manufacturing techniques to ensure safe and effective delivery of genetic material. Additionally, digital tools, like electronic health records, streamline data collection and analysis, improving research efficiency and the reliability of clinical trial manufacturing outcomes.

Personalized Medicine and Customization in Clinical Trials

Personalized medicine aims to tailor treatments to individual patients based on genetics, lifestyle, and environment. This approach has led to customized and adaptive trial designs.

Biomarkers help identify specific patient subgroups likely to respond to treatments, making clinical trials more efficient and cost-effective. Adaptive trial designs also allow modifications to study protocols based on emerging data, ensuring relevance and effectiveness throughout the clinical research process.

Challenges in Clinical Trial Manufacturing

Clinical trial manufacturing faces unique challenges. These include maintaining supply chain integrity and managing scale-up processes effectively.

Ensuring Supply Chain Integrity

Clinical trial materials often involve components sourced from different locations worldwide. Coordinating supply chains and ensuring proper storage, handling, and distribution is critical to maintaining material quality.

Using disposable equipment, pre-sterilized containers, and closed-process systems minimizes contamination risks. Contract or shared cGMP manufacturing facilities and testing labs also provide infrastructure and expertise to uphold supply chain integrity.

Managing Scale-Up Processes Effectively

As clinical trials progress from early phases to larger-scale studies, demand for trial materials increases. Manufacturers must scale up production without compromising quality or consistency.

Scalable manufacturing processes should be optimized and validated to ensure efficiency. Project management also plays a crucial role in scaling up. This includes creating a detailed plan, allocating resources, and monitoring progress to meet deadlines.

Discover Upperton's Clinical Manufacturing Capabilities

Conclusion

Clinical trial manufacturing is a vital part of drug development, requiring adherence to cGMP regulations and navigating regulatory guidelines. Understanding clinical manufacturing processes, material selection, and regulatory compliance is crucial for success.

Technological advancements and personalized medicine are transforming the industry, offering new opportunities and challenges. Maintaining supply chain integrity and managing scale-up processes effectively ensure clinical trials remain successful and compliant.

By following these principles and working with experienced CDMOs, you can successfully navigate the complexities of clinical trial manufacturing, moving efficiently from research to commercial readiness.

Let's work together

How can we help you?

Frequently Asked Questions

What Are the Major Differences Between Clinical and Commercial Manufacturing?

Clinical trial manufacturing and commercial manufacturing have some key differences. Clinical trial manufacturing focuses on producing drugs for use in clinical research, while commercial manufacturing is geared towards producing drugs for the market. The requirements and regulations for clinical trial manufacturing are often more flexible than those for commercial manufacturing. Additionally, commercial manufacturing typically involves larger-scale production and a more standardized manufacturing process, while clinical trial manufacturing may require more customization and flexibility to meet the unique needs of clinical research.

How Do Regulatory Agencies Influence Clinical Trial Manufacturing?

Regulatory agencies play a crucial role in influencing clinical trial manufacturing. They set and enforce quality standards and guidelines for the manufacturing of investigational medicinal products. These standards ensure the safety and efficacy of clinical trial materials and protect the rights and well-being of trial participants. Regulatory agencies also review and approve clinical trial protocols and study designs to ensure they meet ethical and scientific standards. Compliance with regulatory requirements is essential for the successful conduct of clinical trials and the eventual approval of new treatments.

How important is quality control in the manufacturing of products for clinical trials?

Quality control is of utmost importance in the manufacturing of products for clinical trials. Ensuring that investigational medicinal products meet strict quality standards is crucial for the safety and efficacy of trial participants. Quality control processes help to identify and rectify any deviations or impurities in the manufacturing process, ensuring that the final product is consistent, reliable, and meets regulatory requirements. By maintaining high standards of quality control, clinical trial manufacturing can uphold integrity, accuracy, and reliability in research outcomes.