- What we do

-

-

Routes of delivery

- Oral

- Nasal

- Nose to Brain

- Pulmonary

- Parenteral

-

Development stage

- Pre-clinical

- Phase I to Phase II

- Phase III - Commercial

Our Approach

- Selecting Your CDMO Partner

- Project Management

-

- About us

-

-

A CDMO like no other

- About Us

- Our Facilities

- Our History

- Awards and Achievements

-

Leadership Expertise

- Executive Leadership Team

- Board of Directors

- Careers

-

-

- Resources

- Events

- Contact

Analytical Services Fact Sheet

Supporting Preformulation, Formulation Development, Quality Control and Stability Testing of APIs and Final Dosage Form

Upperton provides an extensive range of analytical techniques to generate critical product data from the early stages of development through to QC testing of clinical supplies. This data guides formulation development and is used to assess stability and evaluate the performance

and quality of the final dosage form.

Preformulation/Formulation Development

Our scientists recognise that successful development programmes begin with a thorough understanding of the physico-chemical characteristics of the API, and any potential stability or excipient incompatibility challenges.

Traditional Methods

HLPC

Dissolution

Spectrophotometric Analysis

FTIR

Karl Fischer

Physical Characterisation

Laser Particle Sizing

Electron Microscopy

Differential Scanning Calorimetry

X-Ray Diffraction

Dynamic Vapour Sorption

Powder Rheology

Dosage Form Testing

NGI Powder Deposition (Pulmonary)

AINI Deposition (Nasal)

Nasal Spray Characterisation

Dissolution Testing (Biorelevant & Traditional)

Biologics

Gel Electrophoresis

Western Blotting

ELISA

Spectrophotometric Analysis

Sub-Visible Particulates

Assays are developed and qualified to a phase-appropriate level to provide confidence in the

data generated.

Stability Testing

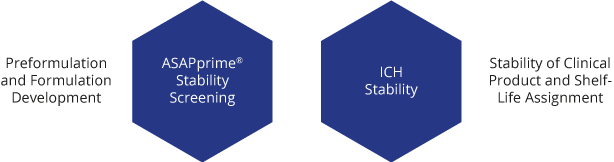

Stability assessment is critical to a successful development programme, regardless of stage.

During the early stages of formulation development, Upperton uses Accelerated Stability Assessment Program (ASAPprime®) to generate phase-appropriate stability data. The use of ASAPprime® helps us to rapidly pinpoint potential instability issues associated with our customers’ API and identify formulation strategies to overcome these stability challenges.

During the final stages of clinical formulation, more formal ICH stability studies on the Technical and Clinical batches will be performed to generate stability data to support regulatory

submissions.

GMP Manufacture: In Process and Finished Product Release Training

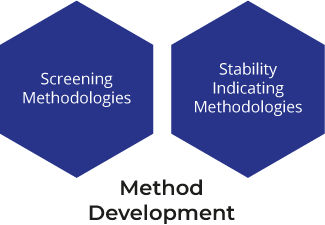

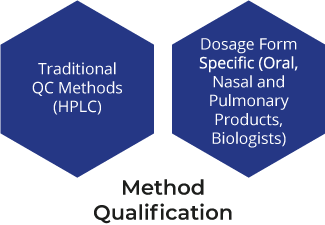

Any analytical methods used need to be robust, yet phase-appropriate and of sufficient quality to support the appropriate regulatory submissions.

QC in process and release testing of clinical products confirm the dose strength/assay in the drug product and the level of any impurities derived from the API. Performance testing may include tablet/capsule dissolution or impaction testing (NGI) to assess the aerodynamic delivery of powder nasal and pulmonary devices. Microbial limits testing is used to ensure that the drug product complies with the relevant specification for microbial quality for the dosage form.